Condensate Recovery

Contents

Lifting Condensate and Contaminated Condensate

Recommendations for special circumstances, including lifting condensate to a higher level return line, and dealing with contaminated condensate.

Lifting condensate from a steam main

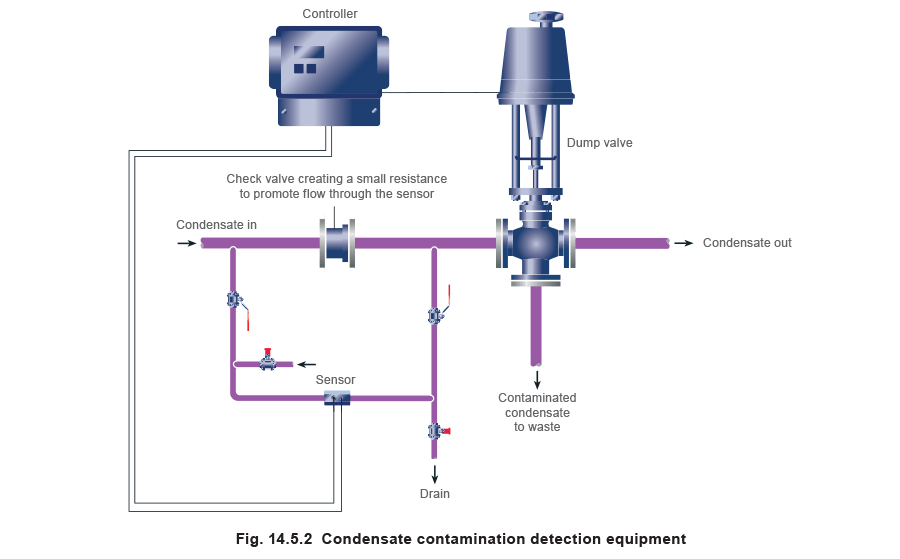

It is sometimes necessary to lift condensate from a steam trap to a higher level condensate return line (Figure 14.5.1). The condensate will rise up the lifting pipework when the steam pressure upstream of the trap is higher than the pressure downstream of the trap.

The pressure downstream of the trap is generally called backpressure, and is made up of any pressure existing in the condensate line plus the static lift caused by condensate in the rising pipework. The upstream pressure will vary between start-up conditions, when it is at its lowest, and running conditions, when it is at its highest.

Backpressure is related to lift by using the following approximate conversion:

1 metre lift in pipework = 1 m head static pressure ≅ 0.1 bar backpressure

If a head of 5 m produces a backpressure of 0.5 bar, then this reduces the differential pressure available to push condensate through the trap; although under running conditions the reduction in trap capacity is likely to be significant only where low upstream pressures are used.

In steam mains at start-up, the steam pressure is likely to be very low, and it is common for water to back-up before the trap, which can lead to waterhammer in the space being drained. To alleviate this problem at start-up, a liquid expansion trap, fitted as shown in Figure 14.5.1, will discharge any cold condensate formed at this time to waste.

As the steam main is warmed, the condensate temperature rises, causing the liquid expansion trap to close. At the same time, the steam pressure rises, forcing the hot condensate through the ‘working’ drain trap to the return line.

The discharge line from the trap to the overhead return line, preferably discharges into the top of the main rather than simply feed to the underside, as shown in Figure 14.5.1. This assists operation, because although the riser is probably full of water at start-up, it sometimes contains little more than flash steam once hot condensate under pressure passes through. If the discharge line were fitted to the bottom of the return line, it would fill with condensate after each discharge and increase the tendency for waterhammer and noise.

It is also recommended that a check valve be fitted after any steam trap from where condensate is lifted, preventing condensate from falling back towards the trap.

The above general recommendations apply not just to traps lifting condensate from steam mains, but also to traps draining any type of process running at a constant steam pressure.

Temperature controlled processes will often run with low steam pressures. Rising condensate discharge lines should be avoided at all costs, unless automatic pump-traps are used.

Contaminated condensate

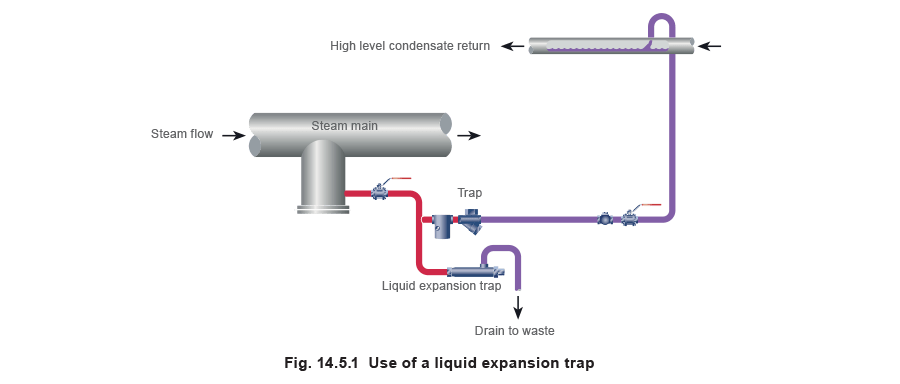

Occasionally, condensate is discharged from sources where it might have become contaminated by corrosive process liquids. This is unsuitable for boiler feedwater because of the dangers of foaming, scaling, and corrosion which it can cause in the boiler and distribution pipes.

However, although contaminated, the condensate still carries the same useful heat as clean condensate which could be recovered if proper contamination detection equipment were employed.

Such equipment detects changes in condensate conductivity. When a change from the desired conductivity occurs then this may mean that the condensate is contaminated. A controller signals a dump valve to open, allowing the condensate to flow to drain.

In some countries, continuous monitoring of condensate is a legal requirement.