Steam Traps and Steam Trapping

Contents

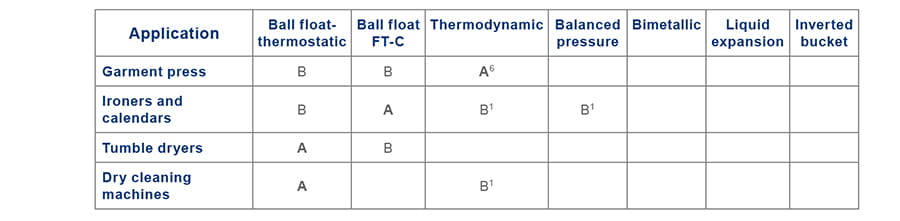

Selecting Steam Traps - Laundries, Presses

Selection tables and advice on trap selection for a range of different processes are included in this tutorial, including calendars, garment presses, dry cleaning machines and tyre presses.

Laundries

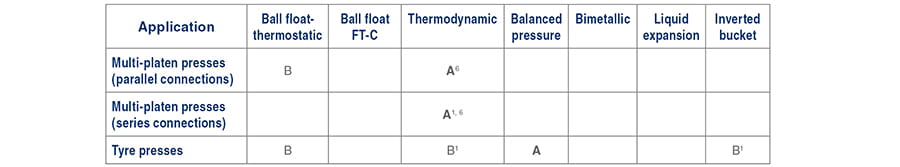

A - Best choice, B - Acceptable alternative,

1 (parallel air vent), 5 (‘near-to-steam’ capsule), 6 (anti-air-binding disc).

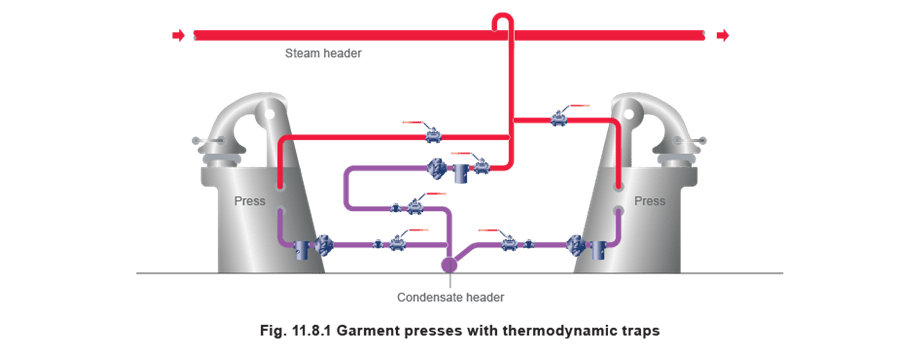

Garment presses

Thermodynamic, float-thermostatic traps, and balanced pressure traps can be used. It is important for each press to have a separate trap (Figure 11.8.1). The head and tables of twin presses should also be individually drained for maximum output.

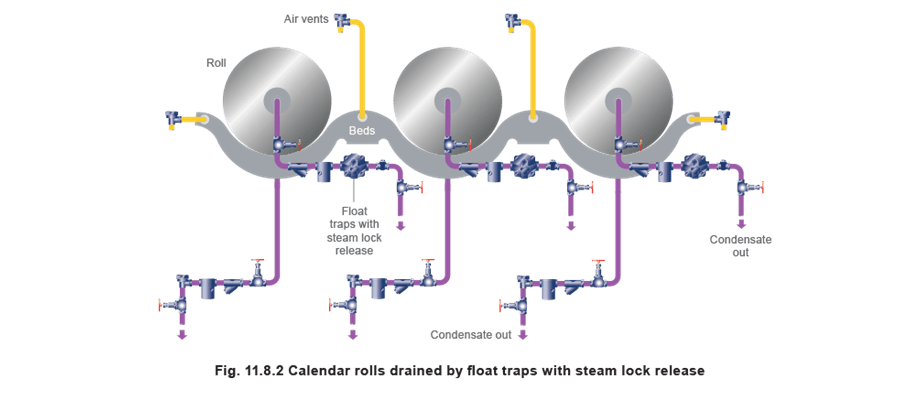

Ironers and calenders

Ironers vary greatly in construction, but in all cases proper condensate and air removal are vital for maximum output. In addition, machines with light fabricated beds may distort and tear the work if heating is uneven, due to air pockets or waterlogging. The steam supply should always be drained, preferably using a separator.

Modern, fully enclosed machines often have the traps fitted all at one end for ease of maintenance, with long pipes connecting the traps from the middle of the bottom of the beds to the drain points. Good results are obtained from thermostatic traps if the long connecting pipes are left unlagged (see Figure 11.8.2), otherwise float traps with steam lock release can be used. Thermodynamic traps can sometimes be used, but it is best if air vents are fitted in parallel. Fit vents to the beds at the point furthest from the steam inlet, and also any heated airing gaps. On the roll, if heated, a float trap with steam lock release is the best choice, although a balanced pressure thermostatic trap fitted on an unlagged line at least 1 m down from the outlet has proven to give good results. If preferred, a thermodynamic trap with anti-air-binding disc can also be used.

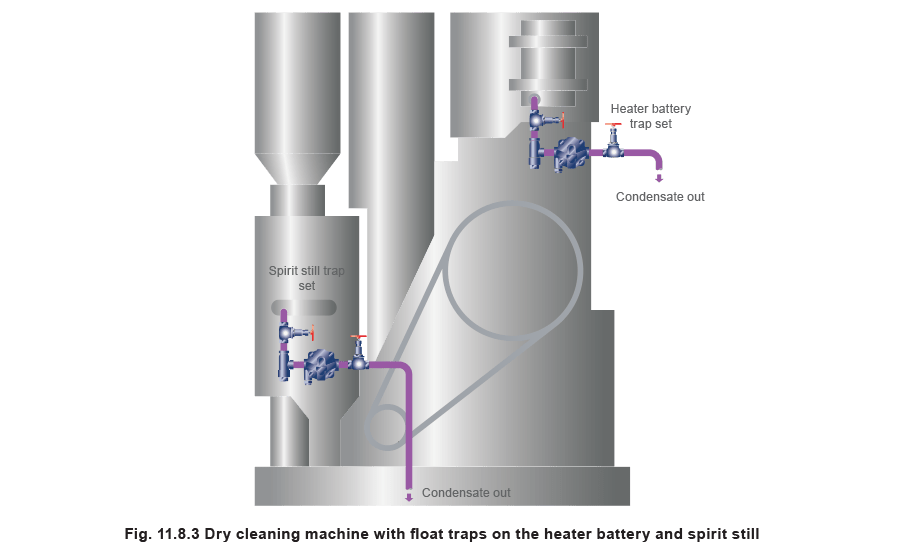

Dry cleaning machines

The air heater battery and the spirit still heating coil should each be fitted with a float-thermostatic trap (Figure 11.8.3). Thermodynamic traps can also be used.

Tumble dryers

The air heater battery should be drained using a float-thermostatic trap but thermodynamic traps can be used with a separate air vent.

Presses

A - Best choice, B - Acceptable alternative,

1 (parallel air vent), 6 (anti-air-binding disc).

Multi-platten presses (parallel connections)

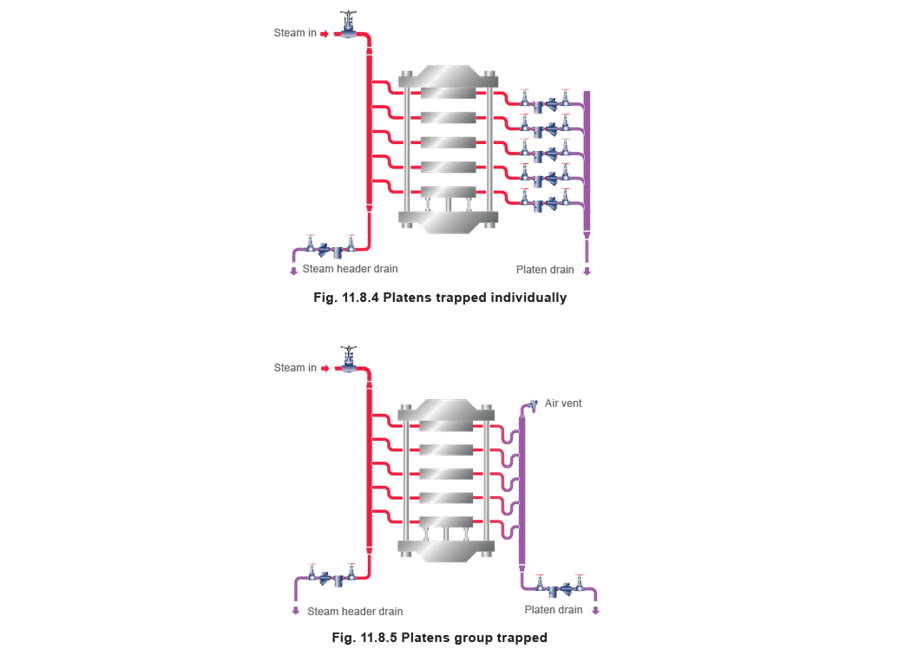

To ensure proper platen drainage, the steam supply connection should be above the platen with the condensate outlet below. Where possible each platen should have its own trap (Figure 11.8.4) but where accurate platen temperatures are not required then the ‘group trapping’ arrangement shown in Figure 11.8.5 can be used. The steam inlet header is drained by a thermodynamic trap. This is also ideal for draining individual platens, as each platen has a relatively small load. Traps should discharge into a generously sized return header through swept connections. This will eliminate back pressure caused by the simultaneous discharge of several traps. If the press is temperature controlled, always use float traps.

The thermodynamic trap is able to withstand the extreme waterhammer which usually occurs with this type of press due to the loops often formed in the flexible steam and condensate connections. However, if these are properly fitted to give a continuous fall, then float thermostatic traps can be used. It may be advantageous to fit an air vent in parallel around the trap, as in Figure 11.8.6.

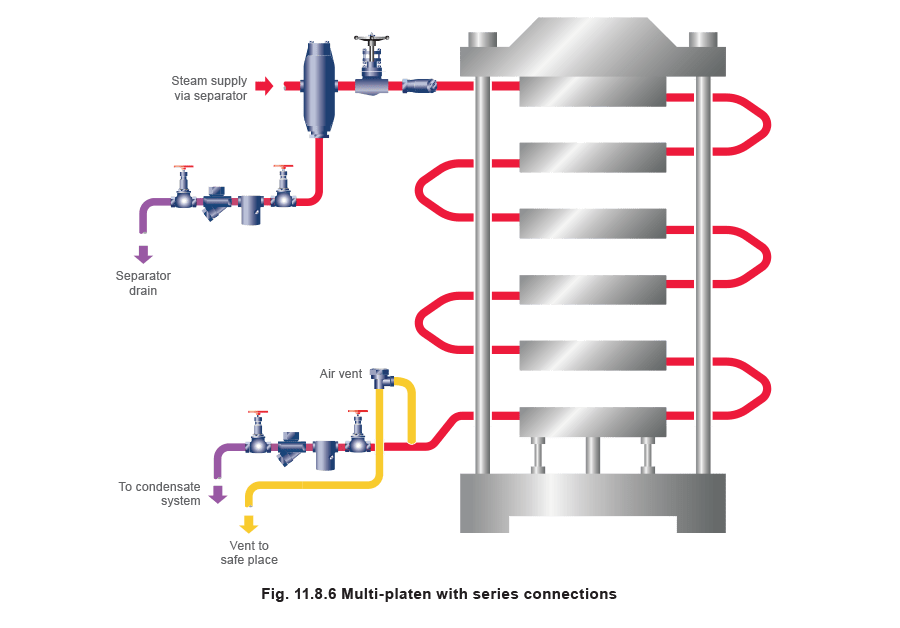

Multi-platen presses (series connections)

This layout is almost certain to have water pockets due to the piping, and the flow of the condensate over the flat platens will be slow. For both reasons use a rugged blast-discharge trap (Figure 11.8.6), which will help purge the condensate out of each platen. This diagram shows the thermodynamic trap with an air vent fitted in a bypass around the trap, but an inverted bucket trap can also be used. The steam supply should be properly drained, and it may be an advantage to fit a separator close to the inlet.

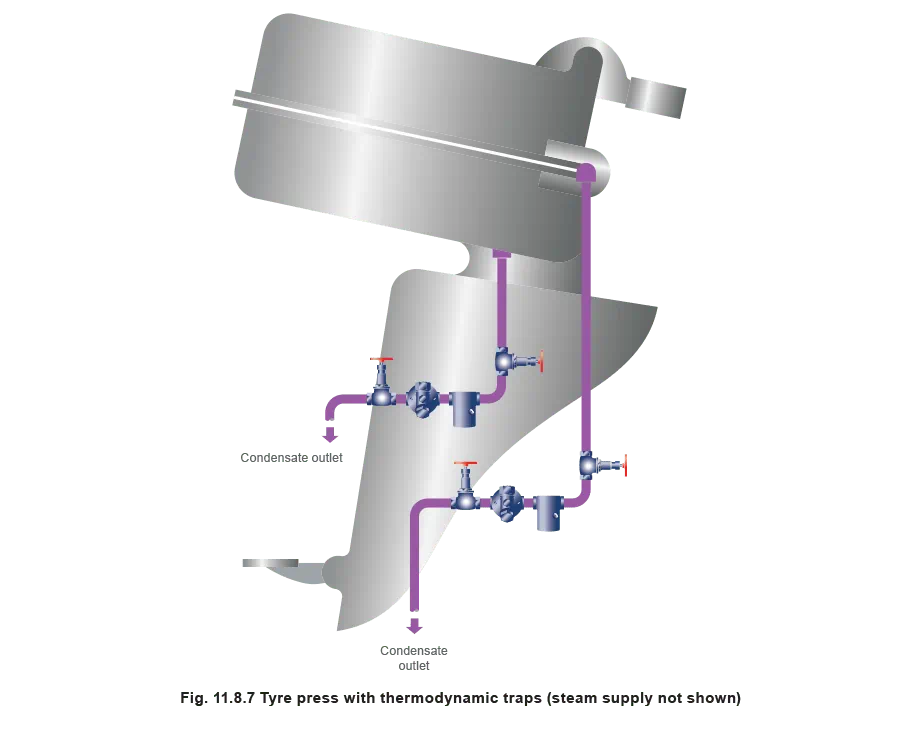

Tyre presses

Good temperature conditions are vital to avoid 'soft' cures. Condensate must be removed as it forms and there must be free discharge of air. Nitrogen (or other inert gases) are sometimes used to add internal pressure to the 'bladder' during the curing process. The selected trap must therefore be able to remove the gas freely or the process times will be extended. In practice, balanced pressure traps seem to give the best results but float-thermostatic and thermodynamic traps (Figure 11.8.7) can also be used. If solenoid or quick acting valves are used to control the process, then inverted bucket traps may be used successfully, in conjunction with separate air vents.