DEFINING DELIVERABLES TO TAKE YOUR PRODUCTION FORWARD

Streamlining your processes will take you so far in achieving optimal productivity while meeting regulatory and safety standards. Is it time for you to gain a greater insight into the potential capability of your steam plant?

We can help you respond to the changing demands on your steam system whether it’s steam generation, making cost savings or improving your steam quality.

HELPING YOU ACHIEVE YOUR OBJECTIVES

Maintaining maximum productivity while meeting increasing operational demands and regulatory requirements can be a challenge.

Whether you are looking to optimise your existing system, or considering future upgrades and expansion, it is important to stop, assess and plan. This activity can help to deliver improvements today, or safeguard future performance.

A steam system audit with an experienced Spirax Sarco engineer is a key action for anyone who wants to make improvements in productivity or ensure regulatory compliance or check safety standards are being met.

Your local Spirax Sarco steam experts can help you find opportunities to get the very best from your steam system, delivering optimum performance when you are looking to expand capacity, increase productivity or simply improve your existing plant.

SPIRAX SARCO PRESCRIBES THE RIGHT TREATMENT FOR PHARMACEUTICAL PLANT

CUSTOMER

Gedeon Richter Plc, Hungary

OBJECTIVE

Identify the cause for increasing number of shutdowns.

SOLUTION

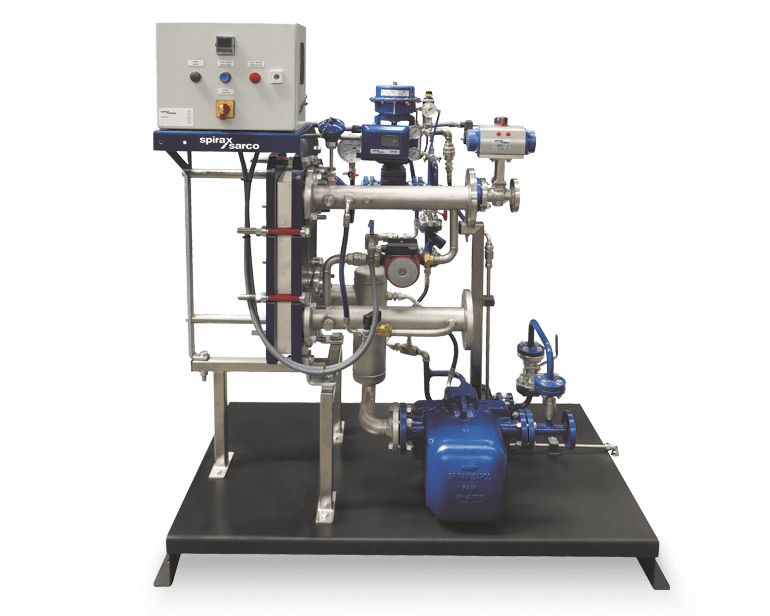

A bespoke solution design to improve the steam line and steam quality.

RESULTS

Reduced maintenance costs and improved productivity with opportunity to replicate in other areas of the business.

IMPROVING THE QUALITY OF YOUR STEAM

Steam quality awareness is growing. For process applications where steam is in direct contact with your product, particularly in the food and beverage and healthcare sectors, the quality of steam is key for consumer safety.

Using the correct grade of steam can reduce contamination risks, help you achieve regulatory and safety standards and improve the quality of your product.

Taking proactive measures to not only increase your productivity, but deliver a better quality product can be as simple as committing to using the right grade of steam.

Your local Spirax Sarco engineer can perform a steam quality check on your existing steam system to help find the right grade of steam for you.

HOSPITAL BOOSTS STEAM QUALITY STANDARDS

CUSTOMER

Waterford Regional Hospital, Ireland

OBJECTIVE

Improve sterilisation standards

SOLUTION

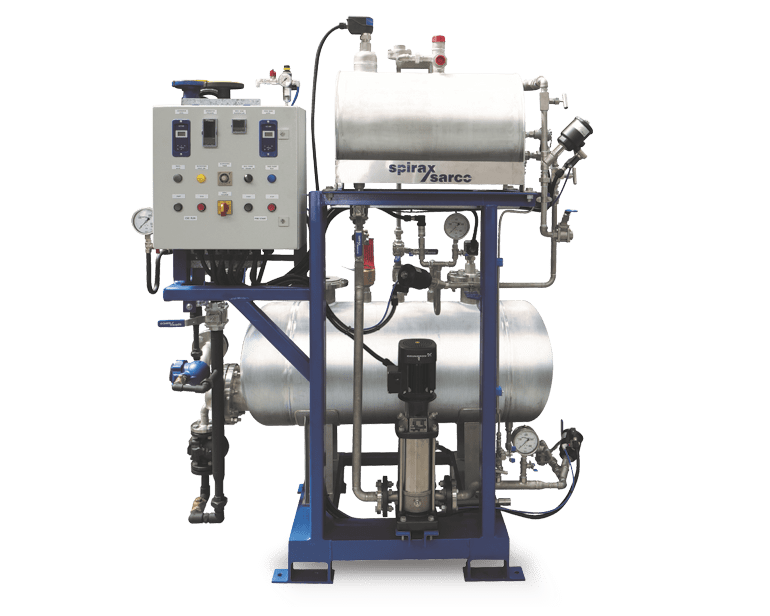

Install Clean Steam Generators

RESULTS

Delivery of dry, stable, high-quality steam.

IMPROVE PRODUCTIVITY IN YOUR PLANT

Can your current steam system cater for increased operational demands?

Can you find a balance for optimal production and cost efficiencies?

Are you struggling to identify sustainable opportunities?

Related to Productivity

Improve System Reliability

There is much to gain from taking a proactive approach to your maintenance of critical production equipment. By working with our steam experts, you can keep your steam plant operating safely and productively.

Strainers and Filters

High efficiency steam strainers and filters for better quality steam.

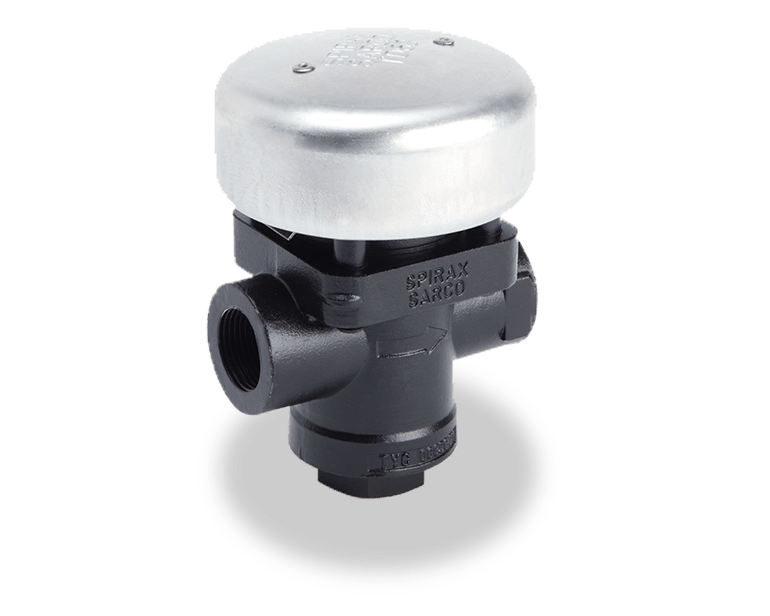

Steam Traps

Removing condensate and air from your system is essential. Returning condensate to the boiler house maximises use of energy. We have the right steam trap for your application and the people to advise you.

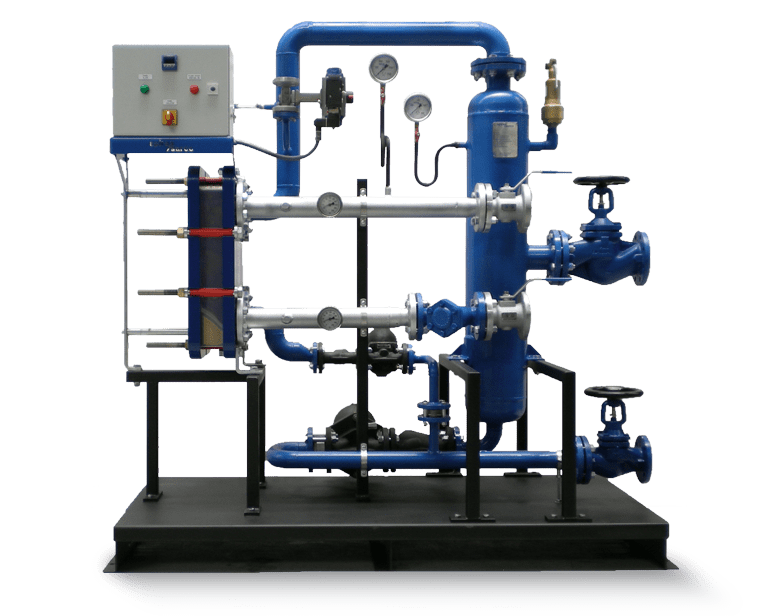

Saving Energy

Operating an energy efficient steam system does not mean compromising on performance. By working together, we can help you to reduce costs and carbon emissions and meet sustainability targets.

Steam Trap Surveys and Management

To run a steam system safely and at peak operational efficiency, it is essential that all steam lines are cleared of condensate properly. This means ensuring that steam traps are working efficiently, a task best achieved by implementing a regular maintenance schedule.

Audits for Optimisation

Choose a steam system audit to benchmark your overall system. We'll scale an audit to your needs, from assessing just a single plant room, right up to your entire steam system.