Clean Steam Generator

for Healthcare Sterilisation

Explore products in this category

Overview

The CSG-HS is a clean steam generation system designed to guarantee steam quality under rapidly fluctuating load conditions that are typical of autoclave demand.

To get the very best from your decontamination process, steam should be dry and free from non-condensable gases (NCGs)*. Designed for maximum performance and reliability, the CSG-HS features an integral degasser that removes undesirable non-condensable gases (NCGs) from the feedwater and delivers good quality dry steam at all times.

*as set out in BS EN 285:2015

Product features

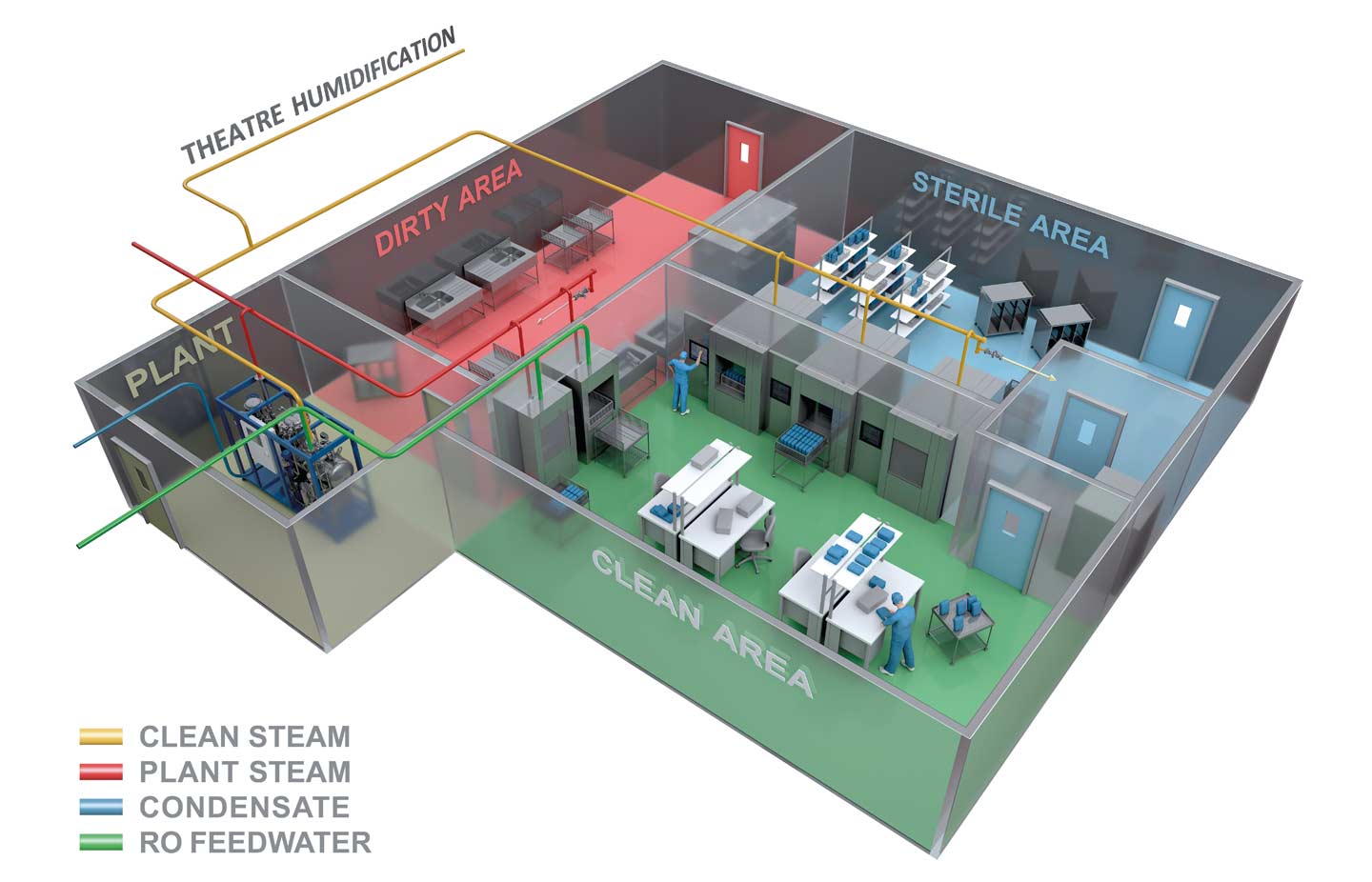

CSG-HS for your Central Sterile Services

The CSG-HS is designed for maximum performance and reliability – a steam supply you can count on without interruptions to your sterilisation processes

Unlike alternative steam solutions, the CSG-HS can be housed externally from your main Sterile Services Department. This means when routine maintenance is required, you can do it without entering the sterile environment – so less risk of contamination and less interruption to your sterilisation processes.

Product range

|

Size: |

CSG - HS - 020 |

nominal production capacity 233 kg/h (513 lbs/hr)* |

|

|

CSG - HS - 055 |

nominal production capacity 620 kg/h (1366 lbs/hr)* |

||

|

CSG - HS - 125 |

nominal production capacity 1384 kg/h (3051 lbs/hr)* |

||

|

CSG - HS - 180 |

nominal production capacity 2016 kg/h (4444 lbs/hr)* |

||

(*) max steam production at reference operating conditions: primary steam at 9 bar g (130.5 psi g), production at 4 bar g (58 psi g), feed water at 20 °C (68 °F).

Design Conditions

| Primary side | Design pressure | 13 bar g |

(188 psi g) |

For a bespoke design contact Spirax Sarco | |

| Design temperature | 195.1 °C |

(383 °F) |

|||

| Secondary side |

Design pressure |

8 bar g |

(116 psi g) | ||

| Design temperature |

195.1 °C |

(383 °F) |

|||

| Safety valve set pressure |

7 bar g |

(101.5 psi g) | |||

| Feedwater |

Design pressure |

8 bar g |

(116 psi g) |

||

| Design temperature |

without pump |

110 °C |

(230 °F) |

||

| with pump | 100 °C |

(212 °F) |

Maximum operating conditions

| Without pump | With pump |

Minimum ambient temperature: 0 °C |

|

| Production |

Clean saturated steam, up to 6 bar g/165.0 °C |

||

| Primary side |

Plant steam, up to 12 bar g/191.7 °C |

||

| Feedwater | P min. ≥ P clean steam + 0.5 bar g (P min. ≥ P clean steam + 7.2 psi g) |

Net positive suction head required (see IM) |

|

| P max 8 bar g/T max 110 °C (P max 116 psi g/T max 230 °F) |

P max 8 bar g/T max 80 °C |

||

Note: Feedwater is recommended to be demineralised or Reverse Osmosis quality to ensure high performance.

Technical Documentation

Title

CSG-HS Clean steam generation system for Healthcare

language

English

reference number

TI-P663-01

Download

Installation Documentation

Title

CSG-HS Clean Steam Generation System

language

English

reference number

IM-P663-02